How to Calculate Crane Leverage with Load and Distance to Prevent Damage to your Property

Calculating Leverage based on Load and Distance for your Crane Rental.

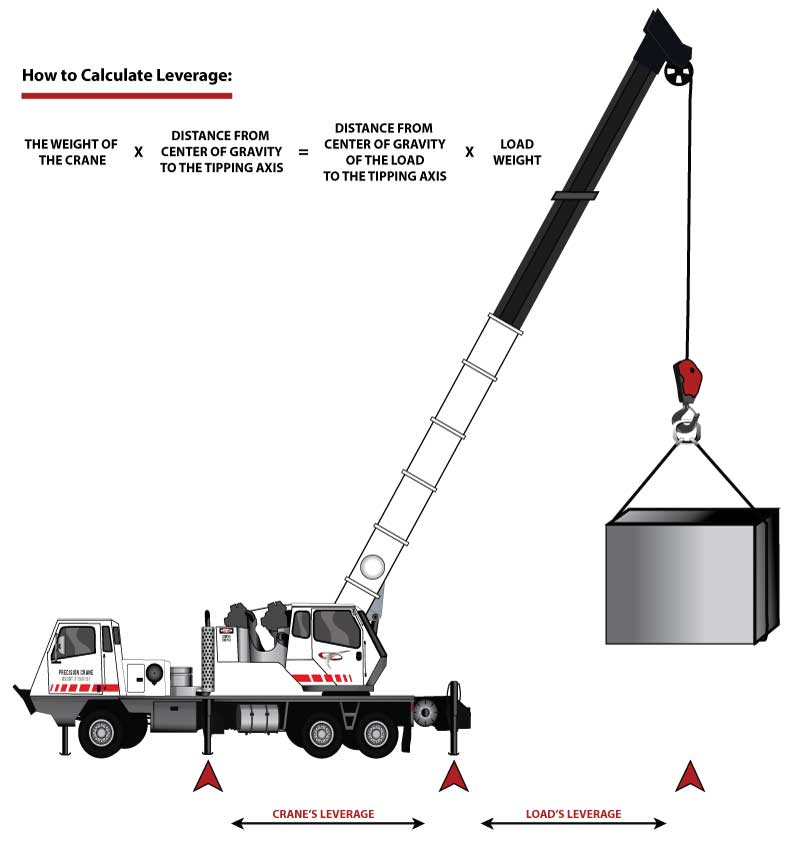

Did you ever wonder how crane services go about calculating crane leverage? How do they figure out the precise leverage necessary to lift objects from one place to another? The truth is most crane services rarely have to calculate the leverage of a lift, but they do need to understand the physics behind it. Let’s take a closer look at the leverage necessary for a crane to move an object from point “A” to point “B”. How does a crane service calculate the leverage required to safely move a large object? The formula for calculating Leverage is simple. Simply take the weight of your crane and multiply it by the distance from the center of gravity to the tipping point. Then calculate the distance from the object being lifted to the tipping point and multiply that by the weight of the object. If the second calculation exceeds the value of the first calculation the crane will become unstable.

When working with cranes, the most important thing is never let the second half of the equation exceed the first half. In fact, any time the loads leverage becomes greater than the crane’s leverage the crane becomes unstable. When a crane becomes unstable it can be very dangerous. It can lead to property damage, injury, or loss of life. Not to mention the possibility of lawsuits as a result of damage inflicted. Therefore, it is unsafe to operate a crane when the load’s leverage is equal to or greater than then the crane’s leverage to weight ratios. That is why a good crane service knows what their crane’s stability load rating is and how much it can safely move. A good operator knows to leave a little “Reserve” for stability. Reserve stability is built into a crane’s stability load ratings. Therefore, it is crucial to choose a crane rental service that has experience moving large objects under many different conditions.

A good rule of thumb is to always use the load rating provided by the crane manufacturer.

Every crane comes with a load rating provided by the manufacturer of that crane. Therefore, a good rule to live by is to never push a crane to its limits, always allow a little reserve for stability. Honestly you should never take unnecessary chances. If a crane was meant to lift more than the manufacturers have rated it for, they would have rated it higher. With a higher load rating they could have charged more for the crane. Always make sure when dealing with cranes that you never cut corners when it comes to safety. More importantly never hire a company that cuts corners on safety. Make sure the company you hire puts safety first always.

We hope you found this information useful.

Visit our website learn more about the different types of crane rental services we have available. In addition, we offer a free online estimate form to help you assess the needs of your project. We are always available to help if you have questions.