Cranes & Power Lines

CRANES & POWER LINES DON'T MIX |

Powerlines Can Pose a Serious Threat when Operating a Crane

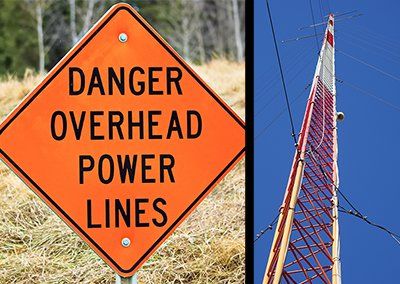

Nowadays, everywhere you look there are power lines. Let’s face it, cranes and power lines do not mix well. A seasoned crane operator will have plenty of experience working around them. When hiring a crane service, make sure that they are aware of all the power lines on and around the job site. If you are unaware of their crane positioning needs, it is highly recommended that they do an onsite visit. If they are unable to do so, another option is to create a 360 degree video of the jobsite. It is imperative to never take unnecessary chances with electric lines. Especially when you are using a crane. When electric lines become broken, they become a deadly threat to everyone and anyone nearby.

Without careful planning you may end up paying for downtime. If the crane service shows up to do the job, and there are lines in the way, they may not be able to perform the task you hired them to do. Most crane service companies will still charge for the crane rental even if they are unable to do a job. Don’t let it be your error in failing to advise the crane company of unsafe conditions. Plan everything ahead of time. Be sure to know where every power line is in relation to the job that you need done. We recommend that anyone working near power lines to work safely. This will prevent serious injuries, save lives, as well as prevent property damage.

Accidents Involving Power Lines can be Dangerous (Even Deadly)

There is one very important thing to remember when working around electric lines. Working at a safe distance from power lines is vitally important. OSHA requires that crane operators maintain a certain distances away from lines. For example, the crane is to be at least 10 feet away from power lines that have voltages up to 50kV. The safe distance goes up as the voltage goes up. Furthermore, for lines with voltages higher than 50kV, equipment must be at least fifteen feet away from power lines. Further guidelines are set for 350kv and up. The safe distance for voltages up to 350kv is at least 20 feet away. Lastly, a distance of 50 feet is required for voltages greater than 350kV. Always better to be safe than unsafe!

It is important to note that often times when using cranes and derricks there are additional steps required before beginning work. If you are planning a job and you have any questions, call your local electric utility company. They will assist you in identifying the voltage of power lines you on your jobsite. In the event that you witness a crane service or heavy equipment operator violating these rules, maintain a safe distance from the crane or equipment, and warn the operator that he should move away from the power line.

When Dealing with Power Lines ~ Make Sure you Choose a Crane Service with Experience

There is one extremely important thing to know about hiring a crane service, especially when power lines are involved. Be certain to hire a crane rental company with plenty of experience working around power lines. When it comes to moving heavy objects from one place to another, specifically around power lines, is not for the newbie. Precision Crane only hires crane operators who have years of practical experience working with cranes or who have been properly trained by them. A family-owned business for over twenty years, we here at Precision Crane always treat power lines and transformers with respect and maintain a safe distance while adhering to OSHA standards.

Always make sure that the company that is providing you with crane services is maintaining a safe distance from electric lines and if they are not, let them know. If they persist in maintaining unsafe practices make sure you report them to the proper authorities or insist that they leave your jobsite immediately. Safety is everyone’s responsibility, as well as liability, which is what occurs where there are unsafe operations. When a crane service works too closely to electricity, they are putting other people at risk as well as themselves. Always put safety first when dealing with electricity.

Thank you for reading our blog! If you have any questions be sure to call us at 814-282-9133 and we would be happy to provide you with any information you need. NEED A LIFT?! We would love to help. Check out our website to learn more about the services we offer and take advantage of our free estimate to begin your project.